Service & Maintenance Question

For the XT 722FE - according to the manual, it appears that...

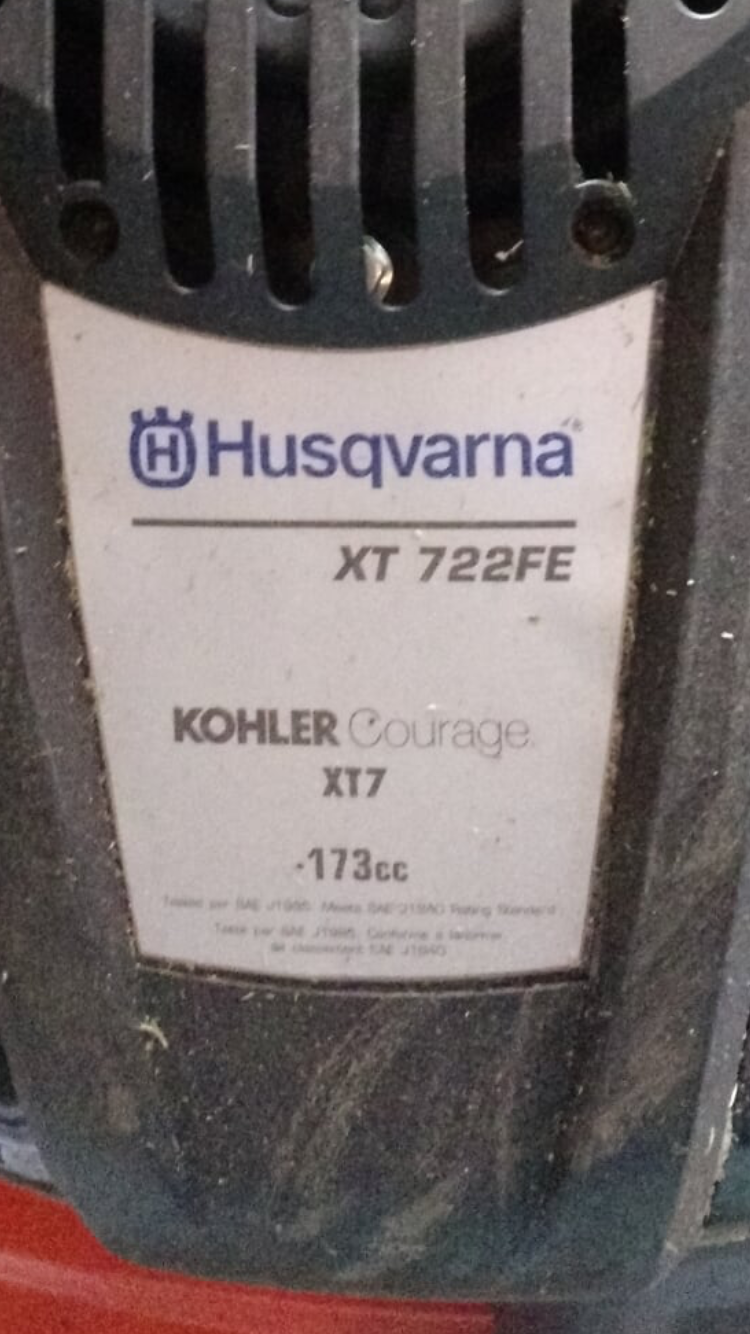

Service & Maintenance Question posted April 23, 2016 by Frances Cruz

45 Views, 5 Comments

Question:

For the XT 722FE - according to the manual, it appears that the engine needs to be removed to get to the starter. Is this correct? Seems like a lot of trouble and I'm wondering if there is an easier way to get to the starter?

Photo:

Answer

All you need to remove is the two blower housing covers.

Be the first to rate this

|

Thank you for the reply. Have you worked on this model / run across this before?

Be the first to rate this

|

I have work on a couple XT7's. Accessing the recoil starter is very similar some Briggs that heavy plastic trimmed. Once the plastic trim covers are remove there only three bolt(screws) or nuts holding on the recoil starter on the metal blower housing.

This should give you a general idea how the covers are assembled. The one at the bottom is the metal blower housing that the recoil is bolted to.

Be the first to rate this

|

Tried your advice. The three bolts that hold the recoil starter are now my issue. The bolt heads aren't accessible because they are inside the assembly. The ends with the nuts are accessible. However, when I turn the nuts the bolts spin too.

Any additional advice?

Be the first to rate this

|

Those are studs shouldn't had been loose but of course corrosion they make hard to to loosen sometimes. Anyway continue loosening them until your able to remove the blower housing. Once remove then remove the nuts from the studs; may need a pair of vise grips to hold the stud. Pay attention to the studs as one is different then the other two according to the IPL. Now reinstall the studs and tighten to the following specs:

Blower Housing Torque

Stud 10 N·m (88 in. lb.)

Nut 8 N·m (70 in. lb.)

Don't forget to put the three spacers on as you install blower housing.

Be the first to rate this

|