Service & Maintenance Question

Commentary:

Like others I had an axle break on a LGT2654...escalated

Service & Maintenance Question posted April 9, 2012 by Garen Post, last edited April 10, 2012

1979 Views, 2 Comments

Question:

Commentary:

Like others I had an axle break on a LGT2654 and also think the axle is under sized for the unit. I've had several tractors and this is my first broken axle.

Problem:

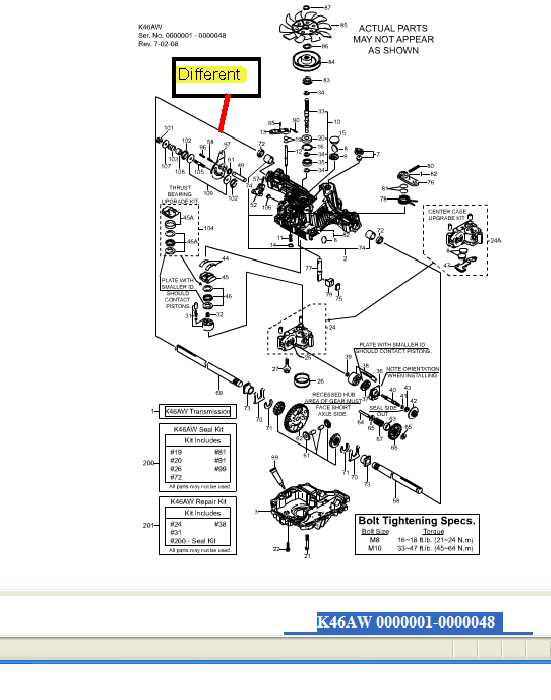

Husqvarna has discontinued part number 532 41 40-06 (the K46BN series transaxle and replaced it with a K46AW series (part number 42119 according to Lowes. I also check with Sears and they confirmed this substitution. The part I received is a Tuff Torq 7A646084090

The ingaging lever is different and I had to modify the switch holder bracket. Unit fit and installed ok, except now my rocker pedal control is backwards. Reverse is forward and forward is reverse. Also the pedeal does not return to the up (neutral) position.

How do I fix or is this replacement transaxle not correct.

Thanks,

glpbubba

Like others I had an axle break on a LGT2654 and also think the axle is under sized for the unit. I've had several tractors and this is my first broken axle.

Problem:

Husqvarna has discontinued part number 532 41 40-06 (the K46BN series transaxle and replaced it with a K46AW series (part number 42119 according to Lowes. I also check with Sears and they confirmed this substitution. The part I received is a Tuff Torq 7A646084090

The ingaging lever is different and I had to modify the switch holder bracket. Unit fit and installed ok, except now my rocker pedal control is backwards. Reverse is forward and forward is reverse. Also the pedeal does not return to the up (neutral) position.

How do I fix or is this replacement transaxle not correct.

Thanks,

glpbubba

Photo:

Answer

Here's the deal: TuffTorq will sell you a pair of new axles (made from higher grade steel for roughly $30) no need for a new or different transaxle. Easy replacement proceedure; pull the transaxle flip it over, pull the pan, replace the axles, PUT IN NEW LUBE, button it up, reinstall). I read about a series of transaxles that operate in the exact opposite fashion dwon to the reverse switch, but didn't understand it until your post.

My experience is that there is one thing you DON'T want to do, That is to reuse the same wheel hub(s). Check the fit of the hub on the axle that broke. The bore will be sloppy and tapered down to the break point. The broken ends of the axle will appear "grainy" - like sand particles; this indicates fatigue; not shear. A sloppy bore creates a fulcrum that works a stress line into the shaft on every revolution. This stress works the bore open (wallowing it open) which moves further into the hub (creating greater and greater mechanical advantage as a fulcrum) until the shaft breaks. Nothing worng with the transaxle, nothing wrong with the motor or load sizing, just a defective hub bore. I didn't discover this until I went into "an autorized dealership" and found three tractors suffering the same issue. Dealerships replace the whole transaxle for big $. When you check the hubs ($30 each) of the broken axles you discover that they are broken 1 to 1 1/2 inches into the bore of the hub; which (again) is stress and not shear. Put the same hubs on new axles, or a new transaxle and you can plan your return trip to the dealership; as you just reinstalled the problem.

Prove this to yourself: Check the fit on the axle that didn't break - it is not the same as the one that broke. More than likely it has a bore that is tight to the shaft; that is the correct fit (shaft to hub). A hub that offers no resistance at installation (slips right on like it was greased) to the axle is not the right fit. In the "old days" salt water was used to make the two components rust together; which eliminated a sloppy bore, but made disassembly all but impossible.

I hope this helps... as the path of going to the seller, manufacutrer, dealership, etc. is frought with roadblocks... trust me on this one.

Be the first to rate this

|

Paul,

Thanks for the information on the hub issue. But this is now a secondary problem.

I've already purchased and installed a new transaxle. My main problem is the forward and reverse issue. Please see original question. I have a call into Tuff Torq but have not received a call back.

Thanks

Be the first to rate this

|