Service & Maintenance Question

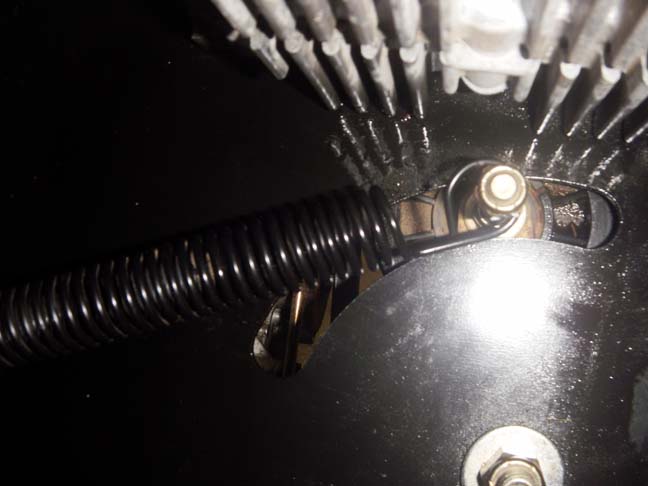

I have a RZ4824 ZTR mower. The transmission levers have lost some responsiveness, both forward and in reverse. In inspecting the unit, I found that the transmission drive belt seems to have excessive deflection in it - a little more than an inch of deflection. My rule of thumb for v-belts is 1/2 inch of deflection. Does the idler pulley need to be adjusted to reduce the amount of deflection? And can you offer advice on tightening the belt? Behind the seat and in front of the engine, I see a half moon slot with a bolt that has a heavy spring attached to the frame and looks like what I need to access to adjust belt tension. I've attached a photo of what I think that I need to adjust. Am I assuming correctly? If so, do I remove the big spring, loosen the lower nut and slide the pulley to get more tension, tighten the bolt and reattach the big spring? Thank you very much for any guidance on this.

Answer

The idler pulley you looking is auto adjusting as as the tension is related.From the image shown there is more than enough on the v-belt. More likely the v-belt is worn out and is slipping on the pulleys due bottoming out in the pulleys especially if you have a lot use on ZTR. I doubt that both Hydro Gear EZTs would go out of service at the same time; although, some performance loss can be expected as the units wear.

Average Rating: 100% (+1/-0)

100% (+1/-0)

|

Thank you, Eugene. Good info on not having to adjust the belt tension. I have 81 hours on this belt - can you advise on typical lifespan and/or replacement schedules? The belt is riding on the bottom of the idler pulley - you can tell by the shiny wear on the pulley.

I have contributed to the problem I believe. My initial issue was a lack of response on the right side only. I was able to limp it into my shop and I decided to do other maintenance while there, which included an oil change. It's not possible to change the oil on the Kawasaki engine without making a mess (at least I haven't figured out how) so I know some oil dripped on the transmission drive belt and I'm sure it is slipping to the point where neither Hydro Gear will operate properly. I can fix that. I guess my main question at this point is: is 80 hours +/- the typical change-out time for a tranny drive belt? At any rate, I guess I'll be buying a new one to see if this solves it.

Related question: Are shop or service manuals available for Husqvarna ZTR's?

Thank you very much for the guidance on this.........Ed

Be the first to rate this

|

The idler pulley itself should a flat type which the back of the belt rideson that flat area. When I said bottoming in the pulleys this occurs on v-shape pulleys where the vee sides of the belt wears. The pulleys themselves can wear the vee wider but is usually not that pronounced except the plastic composite ones.

As the belt life it depends on the environment that it operates in. I have changed belt that only 50hr or less and then others might have close 200 hrs.

As for changing the oil look into an Drainzit hose adaptor. The fitting size for the Kawasaki should be 14mm but double check this size of the drain plug before ordering as it been a while since I add one these hoses.

Here is a link to a website that info on them. You Google or use your favorite search engine once you the PN needed. As the filter change it will always be a little messy there but I usually put rags under it to caught as much as I can.

https://www.equipment2u.com/shop/Drainzit_Oil_Drains/10000501

Average Rating: 100% (+1/-0)

100% (+1/-0)

|

Thanks again for your help, Eugene. I get it on "bottoming out" - senior moment there.

Thank you for the tip on the Drainzit - will definitely pick one up ASAP. Also, can use a small pie plate with rag under the filter to get any oil that drips from removing the filter.

I'll swing by my dealer today and buy a new transmission drive belt. I keep detailed maintenance records on my equipment and will note the hours on the meter when I change it out and then monitor from there.

Last ? - are service/shop manuals available for working on this equipment? I've changed out tran. drive belts on lawn tractors and know that I can figure this out, but also know that a proper manual will save me some time and hassle.

Thanks again for all your advice - much appreciated...........Ed

Be the first to rate this

|

The dealer may have one but I haven't seen any service manuals that are online but that drive belt is fairly easy to change just got remove tension on the belt at the idler. Many have a 1/2 square drive hole for a pull bar; although, some require removing the spring on the idler arm. Its the one in your picture that you posted.

Average Rating: 100% (+1/-0)

100% (+1/-0)

|

Thanks again. My dealer said that Husqvarna doesn't even give/sell service manuals to their dealers.....crazy!? Oh well, I do have the parts book and I can usually figure out what to do if I have that. You excellent advice above has confirmed what I thought. The dealer recommended that I also replace the spring ($10) and I went with it.

I really appreciate the help you've given, Eugene! I don't know what they pay you, bro, but I think a raise is in order.........LOL

Thanks again...........Ed

Be the first to rate this

|

Have a follow-up question, Eugene and need the benefit of your experience again (thanks in advance). Started on this after lunch - getting the tranny drive belt loose was no biggie. But, I've also got to drop the deck drive pulley and clutch from beneath the engine to get the upper belt off. Need to remove the big honkin' spring to release tension on the deck drive belt and it's a mf'er. I've got a spring hook and I'm a big dude, but I cannot stretch that sucker enough get it off the post. I was hoping it had a lever end where I could put a socket and breaker bar to release the spring tension to remove the deck belt, but no cigar. The spring is attached to two fixed posts. Do you have any tips/tricks for removing the big spring on the deck? I've got a good set of tools, but I'm at a loss on how to safely get this big sucker off without just going berserker on it and maybe breaking something. Thought it better to ask first.

Thanks................Ed

Be the first to rate this

|

Another photo to show you what I'm working with.

Be the first to rate this

|

Eugene, never mind on my follow-up question about the spring. I finally realized that I was barking up the wrong tree and just had to push inward on the idler pulley attached to the pivot bushing and not mess with the spring. Major duhhhhhhhhhhhh moment.

Thanks.........Ed

Be the first to rate this

|

Sorry I couldn't reply earlier I was on the road picking up some JD parts for a F525 front mower. Takes 30 mins just to get there and then wait even after called in my parts order. Glad your making progress. I did forget about the PTO electric clutch; just forget about things I do automatically sometimes. Don't forget to put PTO anti-spin brace back on or you can lose the clutch wiring if not damage the clutch itself when the wiring is pulled out as the engine starts. Been there done that myself but after $300 for a new clutch I haven't done it anymore although several customers have.

Average Rating: 100% (+1/-0)

100% (+1/-0)

|

The PTO anti-spin brace - is the the large, brass bushing type part that fits above the clutch and under the tranny drive belt pulley? If so, then I think I'm good, but I did assemble it wrong the first time. The brass bushing thingy kept dropping down on me when I was trying to mate the key in the pulley with the shaft, so I put some grease on it to hold it to the upper pulley while I was finding the keyway. But when I got it assembled, I noticed the clutch spinning and hitting the ears on the hydro gears when I moved it by hand. I knew that had to be wrong, so I dropped the lower pulley and clutch, brought the brass bushing thingy down and reassembled. Now the clutch does not move when I move the lower pulley. Thanks for schooling me on what that was all about. I don't know where you are, but I'd sure like to buy you a beer sometime, bud. This has been a minor PITA, but it will go twice as fast next time and now I also know how to replace the deck belt when that day comes. You've been a big help and I really appreciate it.

Thank you........Ed

Be the first to rate this

|

I think your writing about item 10 in the following image, if so it is just a needed spacer.

What I referring to is item 15 (the large L shape flat bracket) the tip foes the slot of the PTO clutch. I drawn an orange from the tip to the slot for reference. I see that you don't need to remove it but it does needs it tip in the slot when you remount the PTO. Also the retaining bolt for the PTO center needs torquing to 55 ft-lbs. Lucky on many newer PTO they provide flats for a wrench to fit to help with torquing.

Average Rating: 100% (+1/-0)

100% (+1/-0)

|

Aha! Gotcha! I will double check that in the morning. It's O-Beer-30 right now and I'm hanging it up for today.

Thanks once again, Eugene - much appreciated.........Ed

Be the first to rate this

|

Well, better lucky than good any day, right? I had the anti-spin lock in the hole, but it was a combo of luck and common sense. The clutch body really only fits up one way without hitting on the hydro gears and so I figured that part out, but was unaware of the anti-spin lock until you told me about it. Checked and it was engaged from my 2nd installation attempt after I found it spinning, but next time I'll know to line it up the first time. Thanks again, Eugene.

Be the first to rate this

|